|

|

|

|

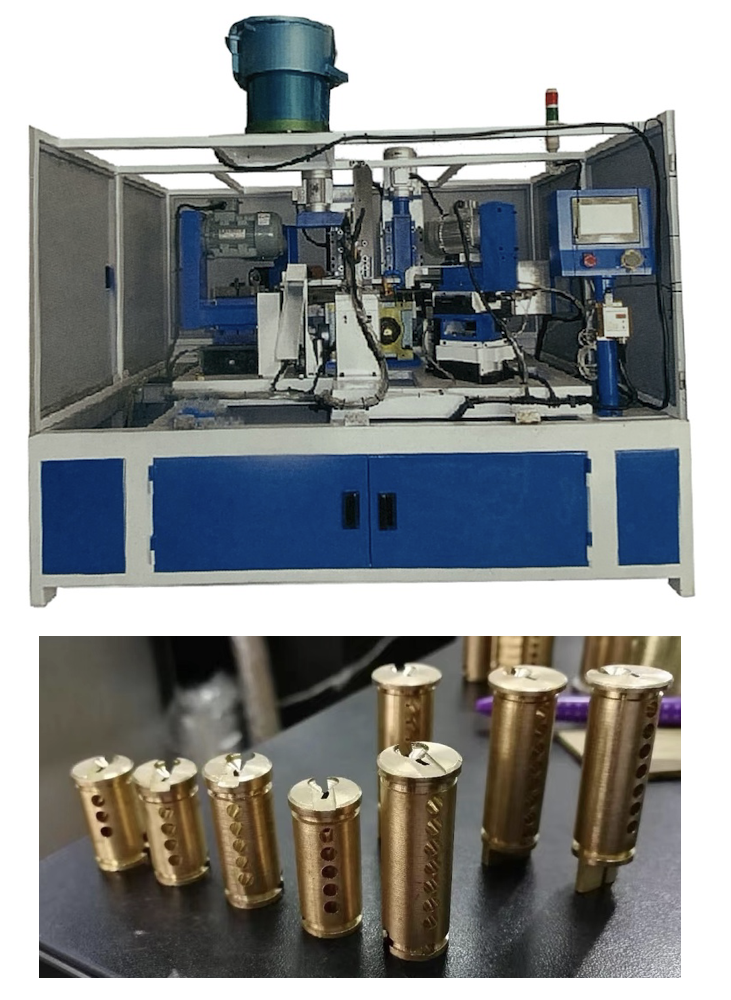

| Automatic Transfer Combination Machine for cylinder drilling |

Automatic index multi-station machines are specially designed for

for lock cylinder processing, having multi-stations, all stations can

operating synchronously, can automatically finish all or some of steps

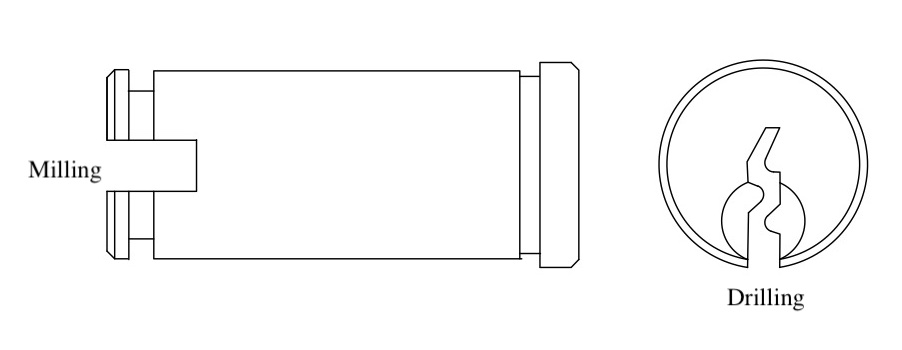

of loading, pilot-hole drilling, pinholes drilling, location-slot milling,

tail lateral milling, tail slot milling and discharging, etc.

|

Features

1/. PLC & HMI control system.

2/. Touch screen set and display machine commands, processing data,

production statistics, error information, and trouble shooting guide.

3/. Servo motor driven, ball screw rod and linear guid rail

transmission make the products with high accuracy and stable

quality

4/. Index rotary parts transferring from one station to next station.

5/. Compact design, combining all or some of pilot-hole drilling,

pinholes drilling, location-slot milling, tail lateral milling and tail

slot milling processing into one unit.

6/. High efficiency, low cost.

7/. Accuracy +/-0.025mm.

8/. Sizes adjustable, for different cylinders.

9/. Operating simple.

10/. With automatic vibrating feeder.

|

|

|

Specification

|

SKLC2 |

SKLC5 |

Applicable material |

Brass£¨cast iron |

Processable size |

25-70mm |

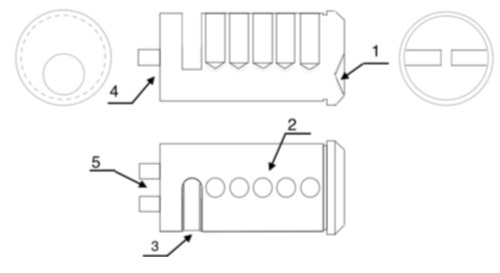

Application: |

S-slot cylinder, I-slot cylinder, computer lock cylinder slot |

Function |

Pilot-hole drilling |

Pilot-hole drilling |

°™ |

Pinholes drilling |

°™ |

Location-slot milling |

°™ |

Tail lateral milling |

Tail slot milling |

Tail slot milling |

Working efficiency, Pcs/ 8 hours |

3000-4000 |

6000-7000 |

Power consumption |

3.5kw |

5.0kw |

Size, m |

1.5x 1.3 x 1.6 |

1.9x1.8x1.7 |

Weight, kg |

1700 |

1800 |

Required air compressor |

4~6 bar |

|

|

|

|

|

|