|

|

|

|

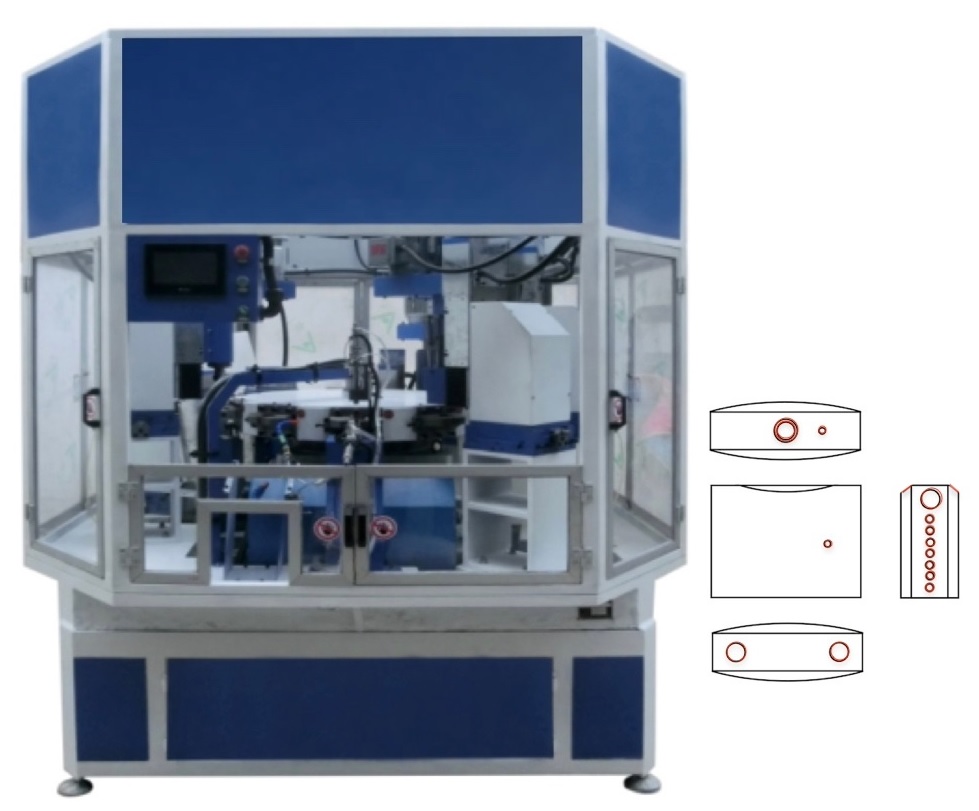

| Automatic Transfer Combination Machine for padlock body drilling |

Padlock Body Drilling Machine SKPBD12 transfer machine is an

automatic Multi-station combination drilling machine, specially

designed for padlock body drilling processing, all stations can operate

synchronously.

|

Features:

1 Hydraulic index rotary transfer system to transfer parts from one

station to next. Once position make sure the match and accuracy

between the holes.

2 Servo motor driven, ball screw rod and linear guid rail , NC controlled

make the products with high accuracy and stable quality

3 PLC & HMI control system.

4 Touch screen set and display machine commands, processing data,

production statistics, error information, and trouble shooting guide.

5 Adopt vibrating feeder, automatic loading and unloading save a lot of

lab cost, reduces the labor intensity of the operator, and increase

working efficiency.

6 Compact design, combining of all drilling, reaming and chamfering

into one unit.

7 High efficiency, low cost.

8 High Accuracy.

9 Sizes adjustable, for different cylinders.

10 Operating simple.

|

|

Process steps:

1. Auto part loading;

2. Drilling shackle pinhole;

3. Chamfering;

4. Drilling shackle holes;

5. Reaming shackle holes;

6. Drilling latch hole;

7. Reaming latch hole and countersink;

8. Drilling cylinder hole;

9. Reaming cylinder hole and countersink;

10. Drilling drain hole;

11. Drilling pin holes;

|

|

| Model: |

SKPBD12 |

| Applicable material: |

BrassúČIron, Zinc, Aluminium |

| Application: |

Square padlock, Arc- Padlock |

| Application size: |

30-70# |

| Working efficiency, Pcs/ hours: |

250-375 |

| Power consumption,kw |

17 |

| Size, m |

2.3x2.1x2.3 |

Weight, kg 3600

|

3600 |

| Required compress air, MPa |

0.6 |

|

|

|

|