|

|

|

|

| Wet Blast Cabinet |

Wet blast cabinets consist of Cabinet enclosure, exhauster, and polyurethane sand pump, can available with cabinet either reinforced fiberglass or 100% stainless steel. Cabinet enclose water and blasting environment to provide efficient blast cleaning while maintaining a clean surrounding work area.

Wet blasting can be used for cleaning and finishing all kinds of parts, produce a smooth, a sericeous surface, a bright shine appearance.

|

Compared to dry blast operation, wet blast does not produce static electricity, is also non-hazardous, dust-free and prevents hours of messy cleaning..

Features:

1. Dust-free wetblasting reduces worker exposure to dust and static electricity build-up generated by dry blasting.

2. 24" long blast gloves wear resistane rubber and protect oprtator hands.

3. Staineless Steel cabinet or reinforced fiberglass cabinet provide rust-free blasting environment.

4. Safety interlocks interrupt blasting if either door is opened.

5. Sopylights brightly illuminates work chamber.

6. exhauster maximizes visibility nside cabinet.

7. Pneumatic powered Windscreen wipers maintains clean window for clear view of work.

8. Foot pedal activates blast process and minimizes operator fatigue.

9. Built-in fingertip-activated squirt gun rinsing the parts inside the working cabinet.

10. Pressure regulator, gauge, and electric switch mounted within easy reach.

|

|

|

|

|

|

|

|

9065W |

|

|

|

|

|

|

|

|

|

|

|

|

| Door opening, mm |

650 x340

(front-top) |

470x610

(side) |

570x630

(side) |

950x950

(side) |

| View Window, mm |

650x340 |

570x230 |

570x230 |

570x230 |

| Light |

18W |

18W x 2 |

18W x 2 |

18w x 2 |

|

|

1.1KW |

1.1KW |

1.1KW |

| Exhauster Fan |

38W |

38W x 2 |

38W x 2 |

38W x 2 |

| Media tank |

water |

20kg |

25kg |

30kg |

60kg |

| media |

4kg |

5kg |

6kg |

10kg |

|

|

reinforced fiberglass or stainless steel |

| Blast gun |

one gun including boron cabide nozzle dia 8mm |

| Squirt gun |

1 pc, dia 2mm. |

| Air source |

5-7bar(kg/cm2), 0.8-1.2m3/min |

| Optional turntable |

---- |

dia 500mm manual |

dia 600mm manual |

dia 800mm maunal or electric 750W |

| Optional |

1. Work car manual or powered & track assembly

2. Turntable manual or electric powered

3. Pneumatic vertical lift door

4. Adjustable gun mount

5. Multiple guns

5. oscillating systems |

|

|

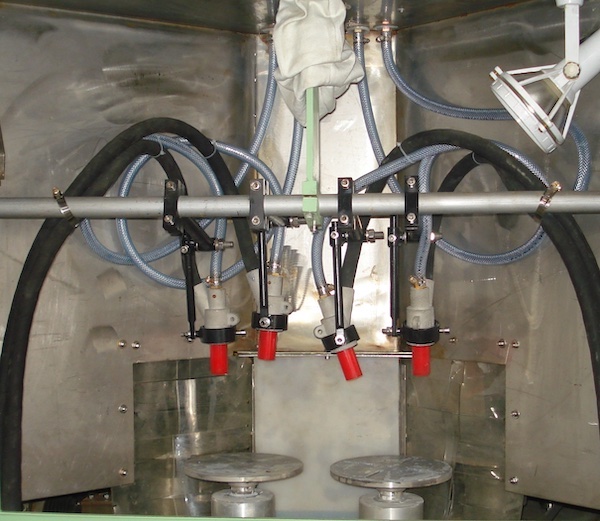

| Automatic rotary indexing satellite turntable wetblast machine |

Automatic rotary indexing satellite turntable wetblast machine consists of cabinet enclosure, a indexing turntable with eight rotary satellites, oscillating system, four automatic suction blast guns, sand pump and PLC control system, etc

It's suitable for automatica precise repeatable blast processing surface of small size components with cones or cylinder shape with no part-on-part contact possible, used for cleaning and finishing all kinds of parts, produce a smooth, a sericeous surface, a bright shine appearance.

Large working chamber allows more options for gun placement and more room for maintenance.

Turntable comes two-station indexing, two parts in each of the blast, and load positions.

PLC controlled Wetblast Cabinet with 8 work piece holding satellites.

Two blast sections with automatic oscillating guns angled for targeted blasting.

Workpiece moves in a rotary motion during oscillated blasting for complete coverage.

During blasting the 2 processed work piece stops at the entry bay for unloading and 2 new work pieces can be loaded.

|

Features:

100% stainless steel construction

Pnueumatic & electrical control panel for work piece door entry

PLC controls work piece rotary motion, blast gun oscillation for effective blasting. Indication panel displays all ovements |

|

|

| Model: |

1212W-4 |

| Main cabinet: |

L1200xW1200xH2000

|

Indexing table:

|

dia 800mm, Speed: 3rpm, motor 750W |

| Satellite: |

dia 150mm, speed: 0-60rpm, motor: 750W |

| Blasting gun oscillating system: |

motor 750W, |

| Blast gun: |

4 pcs. |

| Application parts: |

Dia150mm x H200mm max,

weight: 200kg max. |

|

|

|

Tel/Fax: + 86 755 83660116, info@kaiteindustry.cn, szkaite@hotmail.com

Copyright Kaitexin All rights reserved. |

|

|