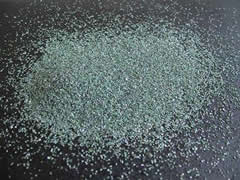

| Green Silicon Carbide |

Green Silicon Carbide is produced in an electric resistance furnace from quartz sand, petroleum coke and salt at high temperature. It's semi-transparet in green color with friability, high purity and high hardness. It's suited for grinding hard, brittle and non-metallic such as cemented carbides, optical glass, ceramics, etc |

|

|

|

| |

| Chemical & Physical Properties |

Crystal Form |

Alpha SiC hexagonal system |

Chemical nature |

Slight acid |

Reaction with acids |

Very slight surface action with hydrofluoric acid |

Reaction with Alkalies |

Attcked at high temperature by alkalles and iron xide |

Oxidation-reduction effects

|

Starts to oxide slowly at 800¡ãC. No reduction |

True Density (g/cm3) |

3.20 |

Hardness

|

Knoop

(kg/cm2) |

2500-2900 |

Moh¡¯s |

9.5 |

Color |

Green |

Color after firing |

Green |

Decomposition point |

2300oC |

Max Usable temperature |

1540oC in air |

Specific heat (cal/g.oC ) |

0oC |

500oC |

1000oC |

0.14 |

0.28 |

0.13 |

Coefficient of thermal conductivity

(cal/cm2.sec.oC ) |

600oC |

800oC |

1000oC |

0.080 |

0.061 |

0.051 |

Electrical resistivity (Wcm) |

25oC |

100oC |

400oC |

800oC |

1400oC |

50 |

46.4 |

26.6 |

7.8 |

0.65 |

Coefficient of liner

expansion (x10-6)

|

25oC -500oC |

25oC -1000oC |

25oC -1500oC |

25oC-2000oC |

25oC-2500oC |

4.63 |

5.12 |

5.48 |

5.77 |

5.94

|

|

| |

Chemical Composition (% by weight) |

Grit |

20# - 90# |

100# - 180# |

220# - 240# |

280# - 400# |

500# -600# |

800# - 1200#

|

SiC Min |

99.0 |

98.0 |

97.5 |

97.0 |

95.5 |

94.0 |

F.C Max |

0.20 |

0.25 |

0.25 |

0.30 |

0.30 |

0.50 |

Fe2O3 Max |

0.20 |

0.50 |

0.70 |

0.70 |

0.70 |

0.70 |

|

| |

| Magnetic Material Content (% by weight |

Grit |

Magnetic material Content

|

16#-30#

|

<0.0180

|

36#-60#

|

<0.0150

|

70#-120#

|

<0.0120

|

150#-220#

|

<0.0100

|

|

| |

| Available grain sizes |

| Grit No. |

Micron |

Grit No. |

Micron |

Grit No. |

Micron |

| 10 |

2360 ~ 2000 |

30 |

710 ~ 600 |

80 |

212 ~ 180 |

| 12 |

2000 ~ 1700 |

36 |

600 ~ 500 |

90 |

180 ~ 150 |

| 14 |

1700 ~ 1400 |

40 |

500 ~ 425 |

100 |

150 ~ 125 |

| 16 |

1400 ~ 1180 |

46 |

425 ~ 355 |

120 |

125 ~ 106 |

| 20 |

1180 ~ 1000 |

54 |

355 ~ 300 |

150 |

106 ~ 75 |

| 22 |

1000 ~ 850 |

60 |

300 ~ 250 |

180 |

90 ~ 63 |

| 24 |

850 ~ 710 |

70 |

250 ~ 212 |

220 |

75 ~ 53 |

|

| |

| Available mircron powder sizes |

|

|

|

|

|

|

|

|

|

|

Standard werte der Mikro-F-Reihe

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| Application |

|

Grinding wheels |

Electrical |

Coated tools |

Heating elements |

Polishing |

Ceramic |

Lapping |

Refractory |

|

|

Tel/Fax: + 86 755 83660116, info@kaiteindustry.cn, szkaite@hotmail.com

Copyright Kaitexin All rights reserved. |

|

|