| Vulcanizing Presses |

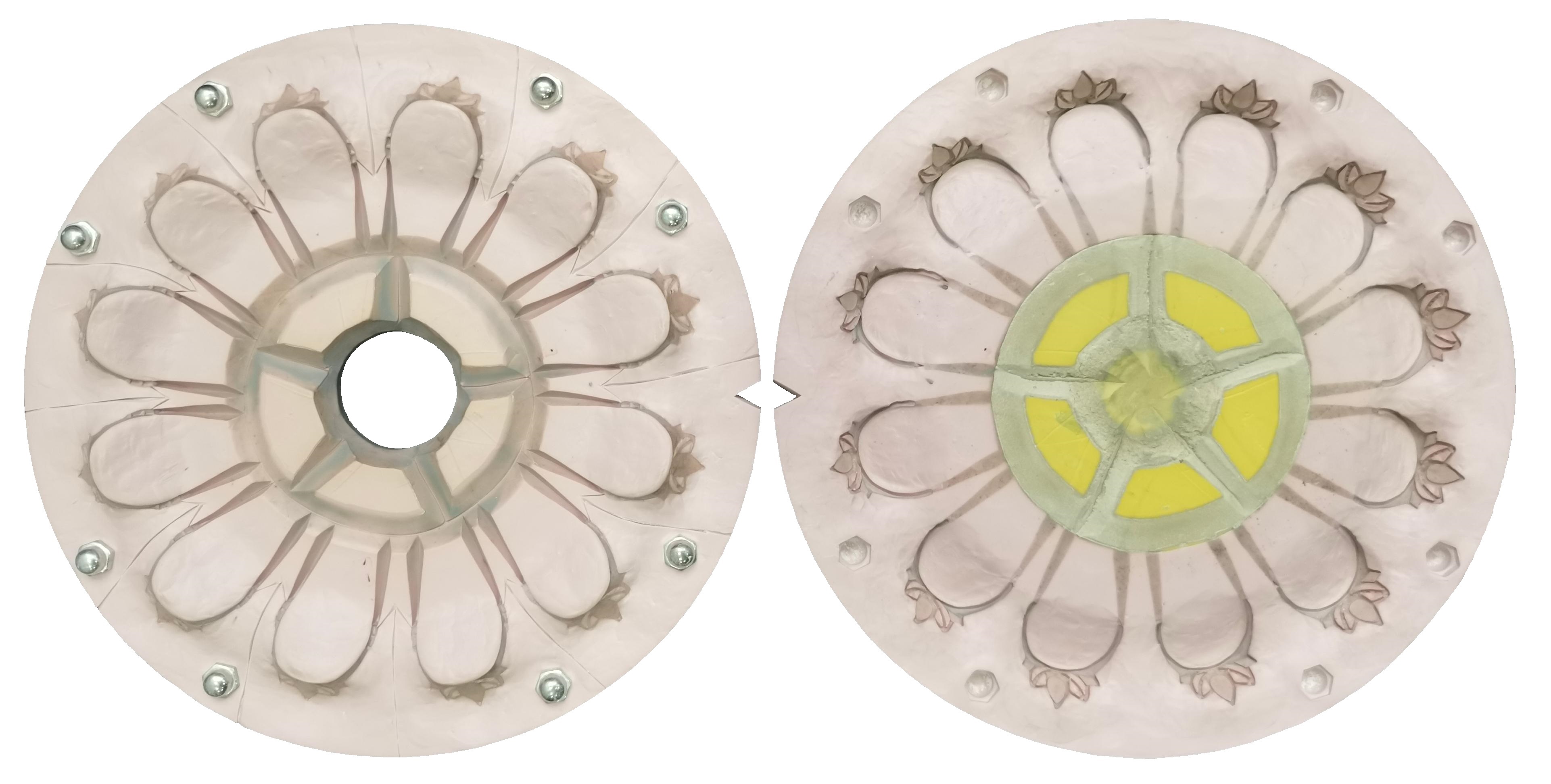

Vulcanizer for silicone rubber

is used to cure or vulcanize silicone rubberproducts. Vulcanization is a chemical

process that involves transforming raw rubber into

a more durable and usable form by cross-linking the polymer chains within the rubber.

Vulcanization is a necessary step to prepare the uncured silicone mold for spin casting production.

A vulcanizer for silicone rubber may consist of a heating elements where

the silicone rubber products are placed for curing. The temperature and duration of the curing process are carefully

controlled to ensure proper cross-linking and achieve the desired mechanical and chemical properties in the finished silicone rubber products |

|

| Automatic vulcanizer PLC controled |

Features:

1. PLC Automatic intelligent vulcanizing control.

2. Touch-screen control panel

3. Automatic pressure regulation.

4. Digital temperature controller.

5. Curing cycle timer.

6. Automatic forced cooling

7. Digital display pressure, temperature and time.

8. Maximum pressure protection

9. Hydraulic group with motor pump and oil pressure release valve.

10. Electro-valve controlled plate opening.

11. Environmental and energy saving insulation design to provide a better temperature uniformity and energy cost saving.

Model |

APM12-I |

APM14-I |

APM16-I |

APM18-I |

APM20-I |

|

12¡± |

14¡± |

16¡± |

18¡± |

20" |

|

150mm |

|

6KW |

6KW |

9.6KW |

10.8KW |

12KW |

| Motor |

1.5KW |

|

32T |

32T |

50T |

50T |

50T |

|

|

|

|

| Automatic vulcanizer |

Automatic vulcanizer for curing silicone or organic rubber moulds.

Features:

1. Automatic control

2. Automatic pressure regulation.

2. Automatic temperature control

3. Curing cycle timer.

4. Automatic forced cooling

5. Digital display temperature and time.

6. Maximum pressure protection

7. Environmental and energy saving insulation design to provide a better temperature uniformity and energy cost saving.

|

APM12 |

APM14 |

APM16 |

APM18 |

APM20 |

|

12¡± |

14¡± |

16¡± |

18¡± |

20" |

|

150mm |

|

6KW |

6KW |

9.6KW |

10.8KW |

12KW |

| motor |

1.5KW |

|

32T |

32T |

50T |

50T |

50T |

|

|

|

|

|

| Manual vulcanizer |

Manual vucanizer press for curing silicone or organic rubber moulds for spin casting.

Features:

1. Automatic temperature control

2. Curing cycle timer.

3. Digital display temperature and time.

4. Heating plates with goods surfaces to assure perfect flatness.

Model |

MVP12 |

MVP14 |

MVP16 |

MVP18 |

MV20 |

Mould diameter, max |

12¡± |

14¡± |

16¡± |

18¡± |

20" |

Mould thickness, max |

150mm |

Heating |

4.0KW |

6.0KW |

9.6KW |

10.8KW |

12KW |

Pressure, max |

32T |

32T |

50T |

50T |

50T |

|

|

|

|

|

| Option: Frames |

| |

| Available mold diameter |

Available mold Thickness |

Remark |

| 6 inch |

14 inch |

Customized from 3mm -10mm. |

1. Other sizes also available upon requested.

2. Aluminum plates available upon requested. |

| 8 inch |

16 inch |

| 9 inch |

18 inch |

| 10 inch |

20 inch |

| 12 inch |

25 inch |

|

| |

|

|

|

| |

|

|

|