|

|

|

|

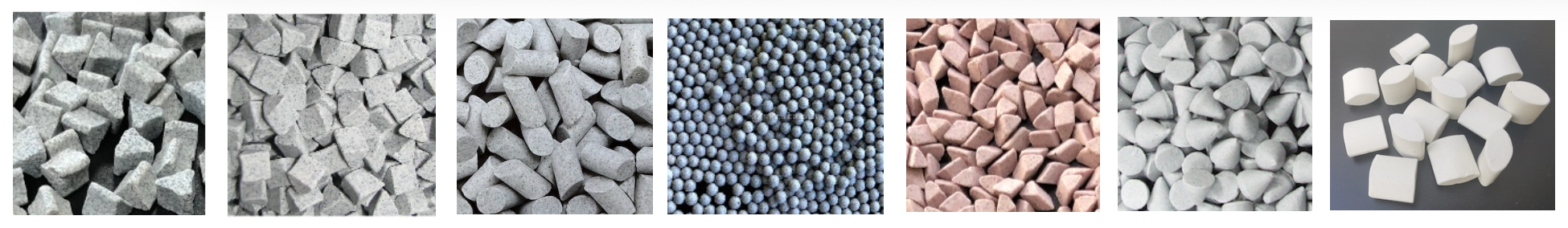

Ceramic Media and Porcelain Media

Ceramic Media are made of high quality of abrasives, such as

brown fused alumina, white fused alumina, pink fused alumina, black

silicon carbide, green silicon carbide, alumina, etc., vitrified

bonded at high temperature. Ceramic medias are widely used in

grinding, polishing, finishing of the surfaces of metal parts with

irregular or regular surfaces for better finish, and also widely

used for chamfering , deburring, scaling oxide, removing rusty stain

as a mass-production method. Ceramic medias find wide applications

in machinery , bearing , electronic, hard-metals, camera, watch,

bicycle, sew-machine, jewelery as well as arts and crafts

industries.

Ceramic media are available in heavy

cutting, medium cutting and light cutting.

Porcelain media are made of alumina, which is mainly

used for fine finishng and burnishing,

can be available in white, yellow

or green color.

Applications:

Automotive industry

Aerospace industry

Medical industry

Surgical instruments

Coin industry

Jewelry industry

Cutlery cleaning

Hardware tools

Stone industry

Casting parts

Forging parts

Stampings

Turn and Milled parts

3D printing

|

|

|

|

|

|

|

|

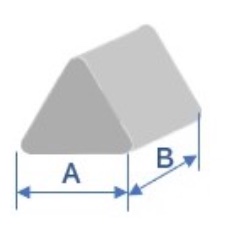

| Shape |

|

|

|

|

|

|

|

| |

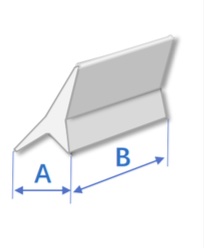

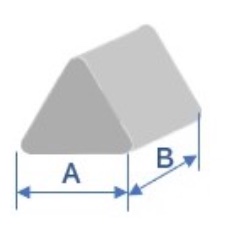

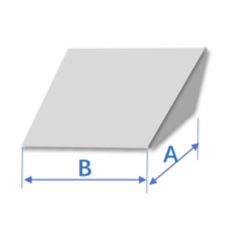

Triangle |

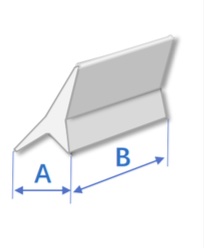

Angle-cut triangle |

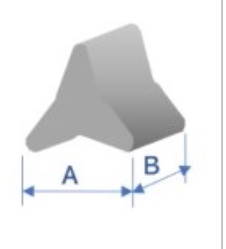

Tristar |

Angle-cut tristar |

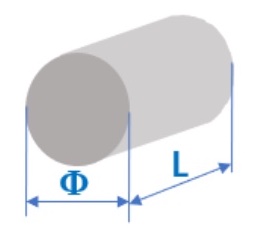

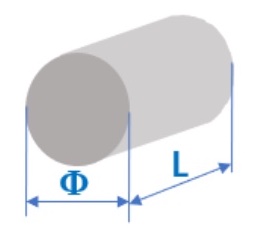

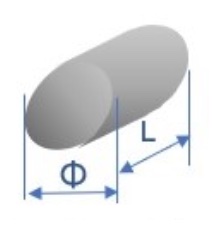

Cylinder |

Angle-cut cylinder |

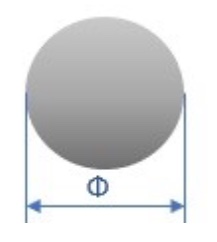

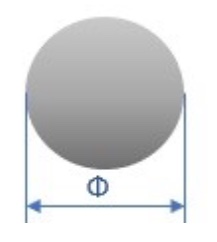

Ball |

| Grinding Perfomance |

A x B |

A x B |

A x B |

A x B |

¢ x L |

¢ x L |

¢ |

Very Heavy Grinding

Heavy grinding

Middle grinding

Fine grinding

Polishing |

2 x 2,

3 x 3,

3 x 6,

4 x 4,

4 x 6,

4 x 8,

5 x 5,

6 x 6,

8 x 8,

10 x 10,

12 x 12,

15 x 15,

18 x 18,

20 x 20,

25 x 25,

30 x 30,

30 x 40,

35 x 35,

40 x 40, |

3 x 3

3 x 6,

4 x 4,

4 x 6,

4 x 8,

5 x 5,

6 x 6,

8 x 8,

10 x 10,

12 x 12,

15 x 15,

18 x 18,

20 x 20,

25 x 25,

30 x 30,

30 x 40,

35 x 35,

40 x 40, |

4 x 4,

5 x 5,

5 x 10,

6 x 13,

7 x 5,

7 x 10,

10 x 6,

16 x 6,

16 x 16,

22 x 8,

22 x 10,

22 x 22,

28 x 10,

35 x 16 |

4 x 4,

5 x 5,

5 x 10,

6 x 13,

7 x 5,

7 x 10,

10 x 6,

16 x 6,

16 x 16,

22 x 8,

22 x 10,

22 x 22,

28 x 10,

35 x 16 |

2 x 5,

3 x 6,

4 x 6,

4 x 8,

5 x 10,

6 x12,

6 x 16,

7 x 13,

8 x 8,

8 x 16,

10 x 20,

12 x 12,

12 x 25,

14 x 20,

15 x 25,

15 x 30,

15 x 38,

20 x 20,

20 x 30,

22 x 22,

25 x 25,

25 x 35

40 x 40 |

2 x 5,

3 x 6,

4 x 6,

4 x 8,

5 x 10,

6 x12,

6 x 16,

7 x 13,

8 x 8,

8 x 16,

10 x 20,

12 x 12,

12 x 25,

14 x 20,

15 x 25,

15 x 30,

15 x 38,

20 x 20,

20 x 30,

22 x 22,

25 x 25,

25 x 35

40 x 40 |

1.0,

2.0,

3.0,

4.0,

5.0,

6.0,

8.0,

10.0,

12.0,

15.0,

18.0,

20.0,

22.0,

25.0,

30.0,

35.0 |

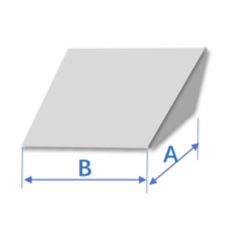

| Shape |

|

|

|

|

|

|

|

|

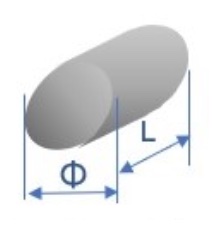

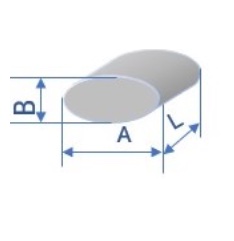

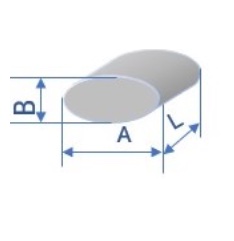

Ellipse |

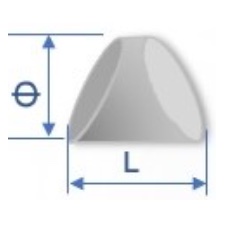

Triangle-cut cylinder |

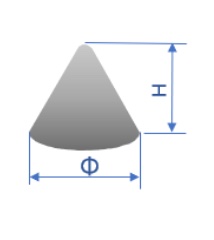

Cone |

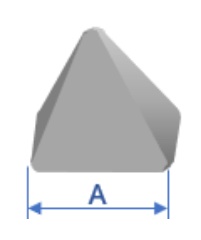

Pyramid |

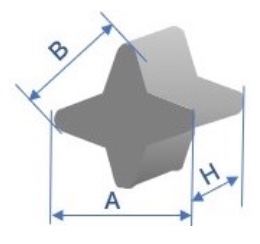

4-star |

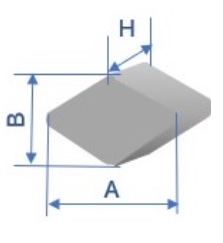

Rhombus |

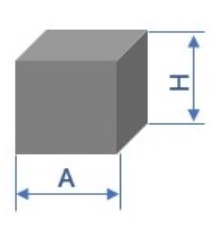

Cubic |

Grinding Perfomance |

A x B x L |

¢ x L |

¢ x H |

A |

A x B x H |

A x B x H |

A x H |

Very Heavy Grinding

Heavy grinding

Middle grinding

Fine grinding

Polishing |

8 x 3 x 8,

10 x 5 x 10,

15 x 7x 15,

20 x 10 x 20,

25 x 15 x 25, |

16 x 16,

12 x 12,

19 x 19,

25 x 25,

50 x 50 |

10 x 10,

15 x 15,

20 x 20,

25 x 25,

25 x 30,

30 x 30

35 x 38 |

10,

15,

20 |

45 x 32 x 15,

18 x 10 x 9.0,

35 x 17 x 11, |

15 x 10 x 10, 23 x 16 x 10, 26 x 25 x 18, 46 x 30 x 20 |

2 x 2,

4 x 4,

6 x 6,

8 x 8,

10 x 10,

15 x 15,

20 x 20 |

|

| |

| |

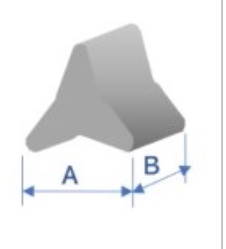

| Porcelain Media |

|

Shape |

|

|

|

|

|

|

|

|

|

Triangle |

Angle-cut triangle |

Tristar |

Angle-cut tristar |

Cylinder |

Angle-cut cylinder |

Ellipse |

Ball |

Density |

A x B |

A x B |

A x B |

A x B |

¢ x L |

¢ x L |

A x B x L |

¢ |

2.7g/cm3 |

2 x 2,

3 x 3,

3 x 6,

4 x 4,

4 x 6,

4 x 8,

5 x 5,

6 x 6,

8 x 8,

10 x 10,

12 x 12,

15 x 15,

17 x 17 |

2 x 2,

3 x 3,

3 x 6,

4 x 4,

4 x 6,

4 x 8,

5 x 5,

6 x 6,

8 x 8,

10 x 10,

12 x 12,

15 x 15,

17 x 17 |

4 x 4,

5 x 5,

5 x 10,

6 x 13,

7 x 5,

7 x 10,

10 x 6,

16 x 6,

16 x 16,

22 x 8,

22 x 10,

22 x 22, |

4 x 4,

5 x 5,

5 x 10,

6 x 13,

7 x 5,

7 x 10,

10 x 6,

16 x 6,

16 x 16,

22 x 8,

22 x 10,

22 x 22, |

1.5 x 3

2 x 5,

3 x 6,

4 x 6,

4 x 8,

5 x 10,

6 x12,

6 x 16,

7 x 13,

8 x 8,

8 x 16,

10 x 20,

12 x 12,

12 x 25,

15 x 15,

|

1.5 x 3

2 x 5,

3 x 6,

4 x 6,

4 x 8,

4 x 14,

5 x 10,

6 x12,

6 x 16,

7 x 13,

8 x 8,

8 x 16,

10 x 20,

12 x 12,

12 x 25,

15 x 15 |

8 x 3 x 8,

10 x 5 x 10,

15 x 7x 15,

20 x 10 x 20,

25 x 15 x 25, |

1.0,

1.5,

2.0,

3.0,

4.0,

5.0,

6.0,

8.0,

10.0,

12.0,

15.0,

18.0,

20.0,

22.0,

25.0, |

3.2g/cm3 |

|

|

|

|

1.7 x 5.2,

2 x 7.5,

3 x 10,

3.5 x 10,

4.5 x 14

5 x 16

7 x 23 |

|

|

1.0,

1.5,

2.0,

3.0,

4.0, |

|

|

Tel/Fax: + 86 755 83660116, info@kaiteindustry.cn, szkaite@hotmail.com

Copyright Kaitexin All rights reserved. |

|

|